One of the commonly held myths about school is that our primary function is to teach children. In fact, our goal is to send home the same number of children in the afternoon that we received in the morning, with the same number of fingers and the same amount of blood that they had when they arrived. Safety is our mantra.

To support that, we hold yearly, mandatory, 30-minute safety briefings for each class. Until every single class (and teacher) has attended a session, we do not open the space for use.

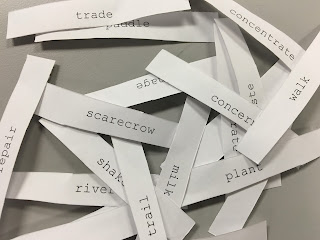

Presenting kids with a long list of rules would be ineffective, not to mention boring. Instead, we have a single safety "Prime Directive." Make the safer choice. That's it. I do have a safety poster with some rules on it, but I don't mention it in detail during the briefings other than to note its presence on the wall. My main goal during the briefing is to communicate respect and trust.

|

| CREATE safety poster. |

I also do some role playing with hot glue guns and box cutters, but that's more to demonstrate to the students that they already know how to behave safely. My favorite "gotcha" question is "How fast are we allowed to run with scissors?" That kills both the running and scissors "birds" with one joke.

We also establish the safety culture in CREATE by differentiating it from other experiences they might have. Their parent (or teacher) might warn them about the consequences of unacceptable behavior with sentences that begin with, "The next time that you...," followed by some threatened consequence. In CREATE, unsafe behavior is zero tolerance. The first time a student chooses to do something unsafe, they are banned from the room for the day. If it happens during lunchtime Tinker Time, they have an immediate conversation about safety with the principal. In the six+ years we've operated CREATE, we've only had to do it three or four times.

Emotions count

When the inevitable small injuries happen, it's important to remember that students mirror our reactions. I always approach minor cuts and burns with an air of empathy mixed with a bit of reassuring nonchalance. A scared child will only ramp up their fear if their adult signals that something serious has happened. Give them 100% of your attention, but under-reacting is the best starting point.

Safety culture needs to reflect and serve the community. If success can be measured by the few minor cuts and hot glue gun burns we've had over the years, our approach has worked well so far.